The acid tanker semi trailer is used for transporting different kinds of acids such as: sulfuric acid, hydrochloric acid, hydrofluoric acid, Nitric acid and Acetic acid among others as used for different industrial applications.

Acid Tanker Trailer produced to transport the chemical liquid with a single compartment, 5,000-gallon sulfate transportation solution.

Chemical liquid transport semi trailer has different requirements for tank material depending on the characteristics of the medium being transported. Common sulfuric acid tank materials are stainless steel, carbon steel, aluminum, etc.

The inside and outside of the tank are treated with fine anticorrosive paint. With no joints, no leakage, corrosion resistance, aging resistance, impact resistance, long life and other characteristics, it is suitable for storage and transportation of most acids and hydrochloric acid. Operating temperature: -20 ℃ ~ 60 ℃.

For the sulphuric acid tanker, TITAN produce the most strong acid tank body to make sure the safety. We adop 5mm thick steel to weld the tankers, also use special design, like the 10 pcs strengthened steel ring to reinforce the Dilute Sulfuric Acid tanker trailer.

To keep the sulfuric acid tankers for sale safety, we use the stainless steel emergency bottom valve also the discharge valves, this type is anti-corrosion, so it can make the chemical tanker trailers to have long service life.

Chemical tanker for sale has different requirements for tank material depending on the characteristics of the medium being transported. Common hydrochloric acid tank materials are stainless steel, carbon steel, aluminum, etc.

The advanced butt welding technology is used in the tank, and the test of high pressure gas leakage after the forming of the tank makes the tank have the characteristics of high strength, stable center of gravity and safe and stable vehicle carrying.

And TITAN adopt famous brand parts for sulfuric acid tanker, it save costs & ensure long-time service. Like JOST, WABCO braking valve etc.

TITAN Vehicle has strong technical force, and can design and manufacture products that satisfy customers.

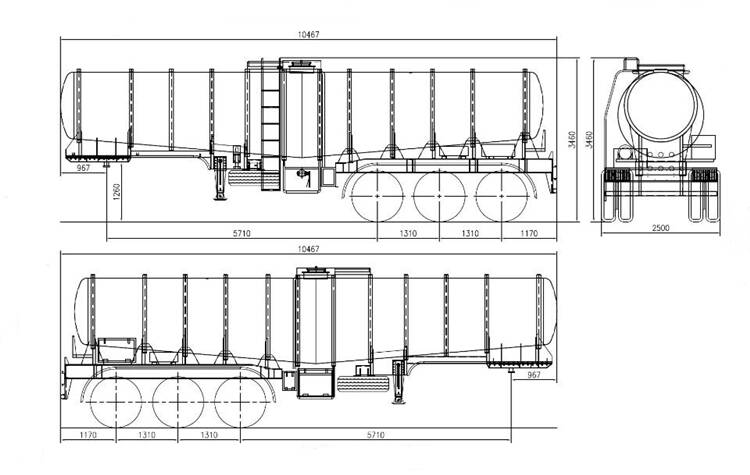

Dimension: 10458mmx2500mm x3450mm (the exact size depends on the final design)

Total volume(m³): 19m³ , Optional 19-42 m³

Tank Body Material: Carbon steel or Stainless steel

Discharging Valve: Diameter is 3 or 4 inch Stainless steel

Axle: 3 axles

Suspension: Mechanical suspension/Air Suspension

Pneumatic Braking System: WABCO

ABS: Optional

Painting: Sandblasted, anti-rust chassis surface is available with 1 layer of anticorrosive primer and 2 layer of top coats.

Accessories: One standard tool box

The long-term corrosion effect in steel chemical storage tank is the continued thinning of the tank wall section, especially at lower levels. This leads to imperfections of the shell.

The service life of these storage tanks is normally estimated to be in the range of about 20-40 years. To guarantee the safe operation of storage tank, the thickness of the tank should be tested once at least every two years, and every five years for an internal inspection at least.

There are quite a number of damage mechanisms that can cause the deterioration and failure of a storage tank. The integrity of a tank structure should therefore be check against, corrosion, chemical attack, erosion, creep, fatigue, mechanical damage and brittle fracture.

In most cases, stainless steel has been the main structural material used for these types of tanks. Steel is prone to just a few products that are mostly acid.

However, stainless steel is resistant against dilute sulfuric acid and dilute hydrochloric acid. For this reason, these acid tanker trailers for sale made of stainless steel cannot be corroded.

Why stainless steel is better?

It is unlikely that steel would contaminate products and if it does, only a few like high quality caustic soda. Steel is an alloy of iron and carbon hence it is prone to attack by rust.

Rust would cause many problems of contamination of these acids if steel was used to make the structure. Owing to this fact and among other reasons, it is unlikely that steel could be used in the construction of chemical tanker trailer of this nature.

Stainless steel is resistant to chemical activity hence cannot be easily corroded away by substances like dilute sulfuric/hydrochloric acid. Stainless steel characteristics are due to the forming of a very thin, passive chromium oxide layer on the surface that prevents further chemical action on the metal alloy. This protective film remains intact hence no corrosion can take place in such conditions.

Inspection work before driving:

1. The vehicle braking, lighting, and turn signal safety systems meet the operating requirements, the tire specifications are qualified, the wear is normal, and the retreaded tires are not used.

2. Safety devices such as vehicle marking lights, signs, reflective signs, side rear protective devices, and fire extinguishers are well configured, and satellite positioning devices are working properly.

3. The chemical tanker for sale number plate is installed intact, the safety inspection signs and insurance signs are placed correctly, the driving license, road transportation license, and road transportation permit for highly toxic chemicals are complete and valid and can be carried with the vehicle.

4. The emergency cut-off device for the transportation of acid tanker trailers for sale is in good condition and is in a closed state.

Safe driving:

1. Choose a reasonable driving route with good traffic conditions, stay away from towns and residential areas, and do not enter the prohibited areas of dangerous goods transport vehicles. Vehicles transporting highly toxic chemicals must be driven according to the time and route approved by the public security organs, and may not be changed at will.

2. Maintain a safe driving speed. In any case, the driving speed should not exceed 80km/h. At night, under low visibility conditions such as rain, fog, snow and snow, you must drive at a reduced speed.

3. Maintain a reasonable driving distance from the vehicle in front, and increase the separation distance in case of rain, fog, snow and other bad weather.

4. It is not allowed to change lanes arbitrarily while driving. Highway traffic must be driven in the specified lanes. Drivers should keep their attention. They should stop and rest every 2 hours or so, and check the technical status of the vehicle in time to ensure that the emergency shut-off valve is closed.

Welcome to leave your inquiry!

We will meet the acme of perfection to serve and provide more details, price, catalog, drawing, videos for you!