Flatbed Trailer ABS system is an abbreviation of Anti-Lock Braking System. It is a very important safety device in a trailer. It is used to prevent the wheels from being locked and dragged during braking, so as to improve the directional stability, steering maneuverability, and shorten the braking distance during the braking process of the trailer, so as to give full play to the braking performance.

Today, we will popularize the use and maintenance knowledge of flat deck trailer ABS.

1. Air leakage in ABS valve of hand brake.

Air leakage of ABS valve when hand brake, but ABS valve does not leak when foot brake, but the working principle of foot trailer and hand brake is the same. It indicates that the braking system of the semi trailer part is not faulty. You should check whether the tractor handbrake valve is leaking or causing air leakage.

2. Leakage of ABS combination valve.

When the ABS do not involve in the work, the pressure of the control line (yellow tube) of the ABS regulator entering the pilot air chamber of the ABS regulator and the output air pressure are in a 1: 1 relationship, so when entering the control line of the ABS pilot air chamber There is a leak in the air, which will definitely cause the ABS output air pressure to drop. The ABS regulator will exhaust the air, causing the illusion of air leakage in the ABS regulator.

You can check by connecting the air pressure between the emergency relay valve and the pilot port of the ABS regulator See if the air pressure is stable when braking or holding the handbrake.

Therefore, when encountering such problems, be sure to check the control pipeline for air leaks, and focus on the key air leak sources such as emergency relay valves, trailer brake valves, and hand brake valves. If you rule out that there is no air leakage in the control line, it is proved that the ABS regulator is leaking. Replace the regulator.

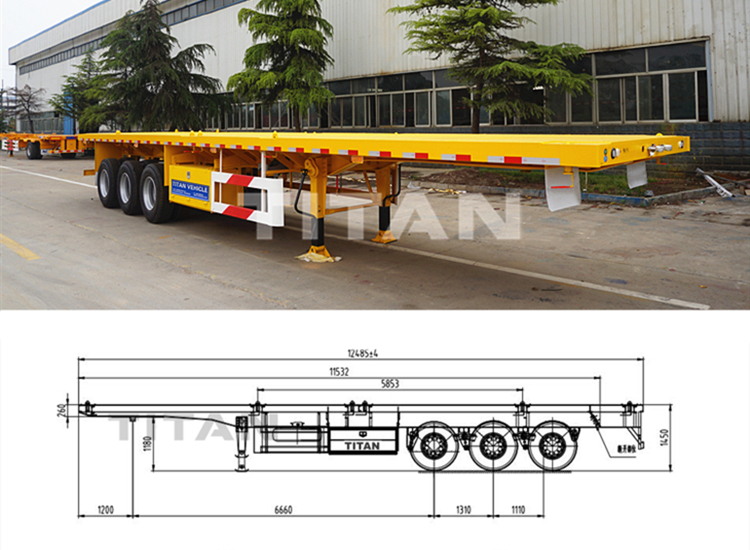

TITAN 3 axle 40ft container flatbed trailer for sale drawing

3. Sensor judgment error.

Because some manufacturers will connect the sensor cable incorrectly during installation (because the truck flatbed semi trailer system is a low choice, it will not affect the performance after connect incorrectly), so when checking the fault, be sure to use the ECU sensor interface (there are 1, 2 above) Four numbers, 3 and 4, among which "1" corresponds to the left sensor of the front axle of the mounting sensor, "2" corresponds to the right sensor of the front axle of the mounting sensor, and "3" corresponds to the rear of the axle of the mounting sensor The left sensor "4" corresponds to the left sensor on the rear of the axle. To find the fault, you must follow the sensor extension line to find the corresponding wheel, otherwise it will be wrong, and you must pay attention to this!

4. Slow brake return.

When you release the brake or handbrake, the emergency relay valve in the control line has poor exhaust, which will cause the brake to return slowly. This phenomenon is generally a slow return of the entire braking system. If the brake system has a slow unilateral return, that is, the brake on the same side of the vehicle has a slow brake return, generally the ABS regulator has a problem, and the regulator needs to be replaced.

If the air pressure of the gas tank of the truck flatbed trailer is insufficient, the spring brake air chamber cannot open, resulting in a drag brake. There is also very little water in the cooling water tank. When the inflation switch is turn on to cool the wheels, the air pressure in the semi trailer gas cylinder will drop quickly, causing the spring brake air chamber to work and drag the brakes.

5. Gap code failure.

During the maintenance or operation of the vehicle, the sensor gap may be excessive. The truck flatbed trailer ABS controller has a fault storage function.

In order to better judge the fault, when the same sensor gap fault is stored more than 8 times, the indicator light is often On, this is to remove the trouble code first, that is, unplug the corresponding faulty wheel sensor, turn on the good switch, it will flash the fault of the sensor, turn off the ignition switch, plug in the sensor, turn on the ignition switch, the indicator light is normal, The code was successfully decoded. If there is only ISO1185 power supply, to find that the wheel has a gap fault, you can press the brake lightly (powering the ABS system) while the vehicle is running, and use the indicator light to determine that the sensor gap of that wheel is defective and adjust it.

Delivery of multiple TITAN flat deck trailers

1. When welding the vehicle, the ABS power harness must be unplugged, otherwise the ECU will be damaged.

2. Ensure that there is no air leakage or lack of air pressure in the brake air circuit of the tractor, and that the tractor has conventional braking.

3. You should always check whether the sensor connector is loose. If you need to replace it, do not insert it incorrectly. Make sure that the gas path corresponds to the sensor one-to-one.

4. The trailer is equipped with a pipeline filter, which needs to be cleaned once every three months to ensure that the pipeline is clean to prevent damage to the ABS.

5. Do not directly flush the combination valve with water when washing the car, otherwise it will cause the ABS system to malfunction.

6. When installing the wheel, push the sensor to the end first to ensure the gap between the sensor and the ring gear. Be careful when installing the wheel hub, and do not install it brutally.

7. When you maintain the wheel, you should pay attention not to damage the surface of the ring gear. If there is dust or oil on the surface of the ring gear, you need to clean the wheel speed sensor.

8. Since most brakes are conventional brakes, ABS does not participate in the braking process. Therefore, it generally does not cause high temperature of the wheel, but abnormal high temperature may affect the sensor.

9. When you apply emergency braking on wet roads, you only need to apply full braking.

10. In the event of a failure, the user must not disassemble the parts of the ABS system by himself, and should consult or contact the ABS manufacturer.

TITAN 3 axle 40ft container flat deck semi trailer for sale

1. TITAN Vehicle adopts high strength steel material to manufacture the flatbed trailer, it can make the flatbed trailer have a higher loading capacity and a longer service life

2. TITAN Vehicle uses automatic arc-submerging welding method to weld the main beam, so the main beam is more stronger and more durable.

3. To make sure the service life of the semi trailers, all the spare parts we adopt are World Famous brand.

4. Also the trailers floor is checker plate, this will keep the other bulk cargo more stable, like the bags, or long stuff.

5. There are 9 cross beams, the distance between two tilted supports is less than 50 centimeters, it can help the main beam have a better loading capacity.

6. TITAN use the oblique angle explosion-proof pipe instead of ordinary plastic pipe, long service life, reduce maintenance costs.

7. TITAN use the 13 ton axle but the 16 ton 220 mm width brake pads which can improve the brake performance 20 %

8. Hight Quality container locks, make sure the stable and safety of the loads.

Through this video below, you can learn about different types of flatbed semi trailer,such as 2 axle,3 axle,4 axle, flatbed etc.

As well as the process, testing, packaging and customer feedback, etc.

If you want more information about our flatbed semi trailer, please click "Flatbed Semi Trailer"

And you can also look at other resources and products on our website.